-40%

Wood 12" Industrial Foundry Pattern~Industrial Brownhoist, Bay City, Mich #250

$ 34.32

- Description

- Size Guide

Description

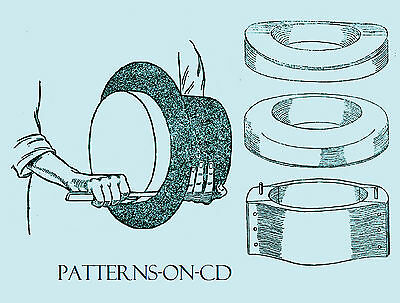

ANTIQUE FOUNDRY WOOD PATTERN FROM INDUSTRIAL BROWNHOIST ~ BAY CITY, MICHIGAN ~ #250This item is a really interesting wood foundry mold.

It measures 12" diameter X 7 1/2" deep.

Pattern #17773 & 122C3 - 10

The mold is in very good condition considering it's age and use.

What a neat piece to add interest to your interior.

This foundry was in business from 1873 to 1983 and made the cranes for the Panama Canal construction.

I have added the following interesting historic information about the Industrial Brownhoist company

Industrial Works (1873-1983)

aka. - Industrial Brownhoist

Foot of Columbus Ave., btwn. Water St. & River - Bay City, MI

Marvin Kusmierz (Dec. 2002 / Updated Jun. 2007)

O

n March 4, 1873 -- a group of local businessmen purchased the

MacDowell Foundry Company

in Bay City, Michigan and began a new business called the

Industrial Works

. This small company eventually became a world leader as a manufacturer of large lifting cranes.

M

any families of Bay County have a history related to the Industrial Works which was later known as

Industrial Brownhoist

before becoming a division of the

American Hoist and Derrick Company

.

Operating for over 100 years

, it established itself as one of Bay County's longest running and most important businesses, providing employment for thousands of workers during its existence.

A

mong the original founders of the company were

George Kimball, James Clements, Edgar A. Cooley, Ebenezer Wells, Ezra Seaman and Phillip Bach

. All were from

Ann Arbor

except for

Kimball

who was from

Saginaw

, where was head of the

Pere Marquette Railroad

office.

O

fficers of the company were:

George Kimball

, president;

James Clements

, vice-president;

Ebenezer Wells

, treasurer;

Charles Wells

(son of Ebenezer), secretary.

T

he company's initial property holding was 100 ft of river frontage that ran to

Water street

and included a 50 x 100 plot across

Water street

. An old wood building for the foundry sat on this plat. A blacksmith shop and several machine shop buildings were located on the riverside of

Water street

. The initial work force consisted of about 25 people. The new company continued in the line of work done by the former

MacDowell Foundry

, which was primarily doing

equipment repair

work for the many local sawmills, and supplying

galvanized piping

used in salt mines. In addition, they added capabilities for supplying

manufacturing saws

(gang and circular) and

building engines and boilers

used by local

sawmills and shipbuilders.

T

he company was formed the same year as the

financial panic of 1873

, and like many other businesses, it struggled financially to survive.

Kimball

, left his position as president and returned to the railroad business, and

James Clements

took over as president. This change proved to be a stroke of luck that would lead the company into a new direction.

I

n 1880,

Kimball

returned to the Industrial Works, not as an employee, but as a customer. He needed to have a

special steam shovel

designed for doing

railroad excavating

, and he wanted the Industrial Works to build it. The company took on the new project which was completed in 1881. It was the

first railroad steam shovel made in the United States

.

I

t wasn't long thereafter that

Sam Edgerly

of the

Michigan Central Railroad

(MCRR) contacted the company. MCRR had designed and built a prototype shovel themselves, and they were looking for an outside source to build a second one.for them. The company got the contract. It was the catalyst that launched the company into a new business direction.

T

he company was very impressed with

Edgerly

's well designed shovel, so much so, they approached MCRR to see if they could

purchase rights the patented design

. MCRR was receptive and an agreement was worked out which

launched the Industrial Works into the locomotive crane manufacturing business

. By 1896 the company had made the transition from a supplier to local sawmills and shipbuilders, and was now a major supplier of cranes to a nationwide railroad industry.

I

n 1895, James Clements died and shortly thereafer, his son William Clements and Charles Wells acquired most the company's assets.

U

p until the entry of the Industrial Works into the crane manufacturing,

Appleby Brothers

of

London, England

was the dominate supplier of large cranes around the world, It was an ideal situation for Industrial Works since they were able to capitalize being the only crane manufacturer based in the United States. Sales grew rapidly and by 1923, Industrial Works had produced and sold 3,776 cranes, of which, 3,261 were for U.S. customers. The company had expanded dramatically. Its manufacturing facilities now covered 29 acres, which included 59 buildings that provided 490,000 square feet of manufacturing space.

B

y 1931 the Industrial Works was facing plenty of competition when the company decided to consolidate its operations with the Brown Hoisting Company of Cleveland which established the

Industrial Brownhoist Corporation

, and helped keep the company's business strong over the following years.

I

n the years that followed the property and some of its building were partially used by various small businesses. But, the atmosphere was like that of a ghost townwere used for a variety of business needs, including storage. The chorus of sounds of a once productive industry were replace by the occasional sounds of a heavy hauler moving stone or the roaring of a single machine. The huge buildings where some of the world's largest cranes were built remain as remnants that reminds us of an era when the river represented industrial wealth to our community.

I

n the early 1990s, community hope and excitement about this river frontage came when local Congressman

Robert Traxler

announced that the

Environment Protection Agency

(EPA) intended to utilize the properties in this area for a Science Park that would include supercomputers. The old IB Administration building was renovated and leased to Unisys Corporation who had the contract to operate the supercomputer. With the supercomputer installed and operating. A government grant was in place to redevelop the property and certainty set in that something good was going to happen along the river.

T

he community was shocked when the government announced after Congressman Traxler retirement that they were dropping their plans for an EPA Science Park here and that the installed supercomputer would be moved out of Bay City! At the time it seemed like a tragedy and even though money granted for the project was turned over to the community allowing redevelopment the property to continue for other uses.

A

little over a decade later, hope and excitement is peaked once again. In 2002, after years of hard work on the part of city and county government, we are in the process of selecting a developer. Early proposals include a series private dwellings, a small business shopping center, an east side harbor and open areas for community use. A short distance to the north a new hotel and conference is being built. At last, dreams of what could be are becoming a reality.

I

t seems fitting that the name "Industrial Works" should somehow be incorporated into the new development. Maybe to identify a road, park or an area in honor of what was once home for one of the worlds largest crane manufacturers. Maybe the name for one of IB's well built old buildings which may become a part of the new development as possibly a parking plaza, farmers market or a huge covered gathering place for community activities.

W

hile I never worked at IB, I did have an occasion to see the operation up close when I was considering a job as an expediter there in the late 1960s. One can not even imagine how enormous an operation it was unless you have seen it first hand. Such an experience is now lost to time and left to the words of history for the inexperienced to try and comprehend.