-40%

HUGE 1900 Nautical Foundry Propeller Pattern ~ S.S.B. Co Philadelphia Ship Yard

$ 6731.99

- Description

- Size Guide

Description

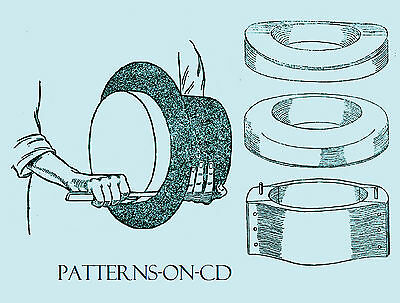

ca. 1900 Wooden Propeller Foundry PatternThis grand, handcrafted wooden foundry pattern was built for the Philadelphia Ship Yard Foundry at the turn of the century to be cast by S.S.B. Co. Foundry patterns were built to create molds, and these molds were wooden tools, carved out or built up to create negative space, which in turn is used to make the inverse form or shape to be used for the casting of metal. In this case, to be used to cast manganese bronze for the creation of a nautical propeller and its base. The molds were made of stacked wood, like a relief. The space or forms that this piece made in the molding material was the the inverse of the final cast piece.

The intended 4-blade propeller was designed to be 17'6" in diameter with a 15-17'3" pitch. It was cast of manganese bronze.

This propeller was saved from destruction by Sculptor Francois Guillemin in the 1990's.

Condition: Original marks, showing evidence pattern measurement, beneath the new, polyurethane finish. Sturdy new support bar.

Measurements: 105" H x 60" W x 40" D.

About Foundry Molds and

the Philadelphia Naval Shipyard

:

Foundry patterns were built to then create molds to replicate a shape. Foundry molds are wooden tools, carved out or built up to create negative space, which in turn is used to make the inverse form or shape to be used for the casting of metal. To make a wooden mold, wood needs to be stacked up, like a relief, or cut out, like a sunken relief, with handles or other pieces to grab and pick up the mold from the molding material. Individual pattern pieces that get packed into the molding material are carved and shaped. The space or forms that these pieces make in the molding material will be the inverse of the final cast piece.

The negative space of the wooden mold is pushed into the molding material, which is typically a large container of sand. This is not your typical sand you find on the beach, but is pushed into the molding material, which is typically a large container of sand. This is not your typical sand you find on the beach, but is mixed with other products to have wet, packing characteristics. The molding or foundry sand is ideal for pouring liquid metal into, as the tiny silica particles will refract the temperature of the liquid. When using a wood pattern to make a cast piece, the interior core pattern shaped like the product needing to be cast is placed between the two outer molds, and sand is poured in. In this process, the molds are pushed together to squeeze the pattern that has been placed in the sand. Once patterns or molds are removed from the molded sand, liquid metal is poured into the impression left by the pattern in the sand. The molding material can then be reused each time to create new metal castings.

Some of the molds we sell here come from factories in the eastern Midwest, where timber supplies were readily available at the end of the 19th century, and the beginning of the 20th century. Most of the time spent making a metal casting is carving and shaping the wood. This is because the cast pieces needs to be structurally accurate, even if the mold itself isn’t structurally strong. The molds are painted to protect the wood. Soft woods are a good choice to make molds, and the wood should have a smooth surface finish so that the mold can be easily removed from the molding material.

From 1877-1920, an industrial movement was in full force. Electricity became a viable source of energy. Mechanization to create products easily and quickly was necessary to keep up with the demand of products. Increased use of factory systems to create products required changes in labor practices. The standards of living increased, as did the availability of products. During this time period, the architecture of the home changed in the type of products used in the home, and the materials that were available to create them.

These antique foundry molds from the Machine Age are a reminder of the nation’s industrial past, a large factor in shaping the culture of the Modern era in America. While these pieces would not have traditionally been found in a residence, the types of industrial forms could have been used in the design of interior furnishings.

The Navy Yard, formerly known as the Philadelphia Naval Shipyard and Philadelphia Naval Business Center, was an important naval shipyard of the United States for almost two centuries.[2] It is now a large industrial park that includes a commercial shipyard, Philly Shipyard.

The United States Navy ended most of its activities there in the 1990s; subsequently, in 2000, the city of Philadelphia took over and began to redevelop the land. The Navy still has a Naval Inactive Ship Maintenance Facility and a few engineering activities at the site.